Green Vehicle Research, Development and Training

Volatile oil prices and concerns with Internal Combustion Engine (ICE) emissions give rise to the recent development of hybrid electric vehicles (HEV) and fuel cell vehicles (FCV). With the abundantly available, clean hydro power in Canada, development of plug-in hybrid electric vehicles (PHEV), extend range electric vehicles (EREV) and electric vehicle (EV) provides more promising solutions to the increasing energy and environment concerns.

The University of Victoria Green Vehicle Technology (UVic-GVT) team has been working on the development of contemporary hybrid powertrain designs with multiple-mode architectures and plug-in capability in the following areas.

The UVic-GVT research and development efforts cover the following areas:

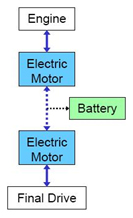

- Development of advanced HEV/PHEV/EREV modeling, simulation and design optimization tools to support better

understanding of the complex,

understanding of the complex,  multiple-mode hybrid powertrain architectures and to introduce the new global optimization based hybrid powertrain design method (past and present HEV design is largely trial and error based).

multiple-mode hybrid powertrain architectures and to introduce the new global optimization based hybrid powertrain design method (past and present HEV design is largely trial and error based).

This fundamental research opens the doors for new knowledge and design innovations for HEV/PHEV/EREV/FCV, and lead to the development of next generation, innovative hybrid powertrain architectures.

- EcoCAR: The NeXt Challenge program - development of next generation hybrid vehicle technology and training of future hybrid technology leaders

The focus of this design competition is to develop and integrate technologies that will reduce petroleum energy use, fuel  consumption and emissions while at the same time provide the consumer with a fully-functional and marketplace ready vehicle. The UVic EcoCAR team is

consumption and emissions while at the same time provide the consumer with a fully-functional and marketplace ready vehicle. The UVic EcoCAR team is  developing an innovative 4WD, two-mode plus, EREV on the 2010 Saturn VUE platform with a 2.4L flex-fuel (E85 ethanol capable) engine, GM 2-mode hybrid transmission, a UQM Powerphase 125 rear traction motor, a newly designed 21kWh A123 battery pack, as well as new vehicle electronic control unit (ECU) and power management system. The UVic team is proud to be one of 17 universities across North America selected to participate in this prestigious competition and to win the second place overall and six other major awards during the first year competition in June 2009. Drs. Z. Dong and C. Crawford are the faculty advisors of the UVic team. The UVic EcoCAR Team Awards include:

developing an innovative 4WD, two-mode plus, EREV on the 2010 Saturn VUE platform with a 2.4L flex-fuel (E85 ethanol capable) engine, GM 2-mode hybrid transmission, a UQM Powerphase 125 rear traction motor, a newly designed 21kWh A123 battery pack, as well as new vehicle electronic control unit (ECU) and power management system. The UVic team is proud to be one of 17 universities across North America selected to participate in this prestigious competition and to win the second place overall and six other major awards during the first year competition in June 2009. Drs. Z. Dong and C. Crawford are the faculty advisors of the UVic team. The UVic EcoCAR Team Awards include:

- 2nd Place Overall

- 1st Place Best Technical Reports

- 1st Place, MathWorks Modeling Award

- Best Electrical Systems Presentation

- 2nd Place, Hardware-in-Loop Evaluation

- 3rd Place, dSPACE Embedded Success Award

- Best Media Relations Program

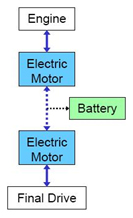

- Development of a generic and flexible low-speed fuel cell hybrid electric vehicle model using MathWorks SimDriveline vehicle powertrain modeling/simulation tool and semi-empirical PEM fuel cell system model

Over the past several years, the research team has developed and updated the semi-empirical PEM fuel cell stack and system models. The model was originally based upon the RMC Ballard PEMFC stack. The parameters of the model were changed using experiment data acquired from our stack tests on a Palcan 1.2 kW PEM fuel cell stack at UVic and improved with additional considerations. To effectively form a fuel cell hybrid electric vehicle model, we are integrating this PEMFC stack/system model into the vehicle performance model constructed using the new MathWorks SimDriveline vehicle powertrain modeling and simulation environment. This will provide us the flexibilities to explore various hybrid vehicle architectures, powertrain component sizes and control algorithms.

Over the past several years, the research team has developed and updated the semi-empirical PEM fuel cell stack and system models. The model was originally based upon the RMC Ballard PEMFC stack. The parameters of the model were changed using experiment data acquired from our stack tests on a Palcan 1.2 kW PEM fuel cell stack at UVic and improved with additional considerations. To effectively form a fuel cell hybrid electric vehicle model, we are integrating this PEMFC stack/system model into the vehicle performance model constructed using the new MathWorks SimDriveline vehicle powertrain modeling and simulation environment. This will provide us the flexibilities to explore various hybrid vehicle architectures, powertrain component sizes and control algorithms.

- Dynamometer tests of low-speed electric vehicle and fuel cell hybrid electric vehicle

Due to the complexity of advanced hybrid powertrain and ESS, and the complexity their interlinked control systems, these new powertrain designs and the control programs need to be extensively tested during the development. Computer modeling and simulation can reduce the needed tests, but can never replace testing. At the same time, testing and experiments using full size prototype vehicles are both expensive and inefficient, due to the high cost, large size and complexity of commercial vehicles, particularly the commercial trucks and buses, and due to the instrumentation challenges for vehicles designed for commercial operations.

We have developed a customized dynamometer for tests of low-speed electric vehicles and fuel cell hybrid electric vehicles. At present, comparable studies on vehicle performance between the experiment results and simulation results, and on the performances of a battery electric vehicle and a PEMFC-battery hybrid vehicle (scooter for the simplicity of testing) with identical powertrain other than the power plants are under way with some preliminary results. More in-depth findings will be reported after the data are processed.

We have developed a customized dynamometer for tests of low-speed electric vehicles and fuel cell hybrid electric vehicles. At present, comparable studies on vehicle performance between the experiment results and simulation results, and on the performances of a battery electric vehicle and a PEMFC-battery hybrid vehicle (scooter for the simplicity of testing) with identical powertrain other than the power plants are under way with some preliminary results. More in-depth findings will be reported after the data are processed.

- Development of advanced HEV/PHEV/EREV powertrain Hardware-in-Loop (HIL) and testing facilities.

The HIL system and vehicle testing facilities are essential for the validation of newly developed hybrid powertrain modeling, simulation and design optimization tools, and for verifying new HEV/PHEV/EREV designs and various complex control algorithms at manageable cost before the expensive prototype vehicle is produced. Advanced HIL system implemented using dSPACE industrial controller for new UVic green vehicles, and chassis dynamometers for low-speed EV/FCV have been developed at UVic.

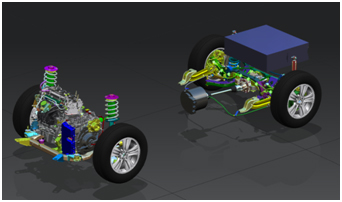

- Development of a general purpose, versatile hybrid powertrain and vehicle testing platform, serving as a intermediate level experimental facility between the HIL and the full size vehicles (SUV and truck)

The availability of a general purpose, versatile hybrid powertrain and vehicle testing platform will allow the UVic GVT team to test and turn advanced hybrid powertrain design and control algorithms prior to the costly development of full-scale SUVs and commercial trucks.

The versatile and low-cost testing platform will considerably speed up the transfer of new technology from research laboratory to company, and make investigation of new ideas quick, effective, and affordable.

- Test of various hybrid powertrain architectures, including series, parallel and power split, two-mode and two-mode plus, and multi-regime

- Test of various energy storage systems (ESS), including various types of batteries, ultracapacitors, and hybrid ESS with both batteries and ultracapacitors

- Development of new hybrid powertrain design for larger commercial vehicles (trucks, vans, and buses)

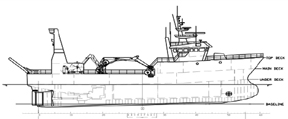

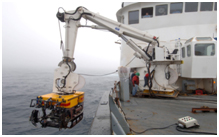

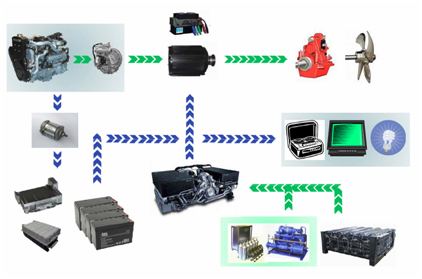

- Green Ship with Advanced Hybrid & Fuel Cell Power Systems

These researches have been extended to the development of Green Shipping technology with advanced hybrid and fuel cell power system for a new UVic research vessel. This extension is part of the Canadian Foundation for Innovation (CFI) project “A University-Based Vessel and ROV Platform for Canada's West Coast” led by Dr. Kim Juniper, and participated by five west coast universities with supports from CFI and the province of British Columbia. This new addition broadened the UVic GVT work to more generic Green Transportation area, covering the research, developments, industrial collaboration and training on environment conscious automotive and marine applications.

- The Vessel - A Mobile Ocean Observatory Node and Research Centre (CFI Led by Dr. S. Kim Juniper, School of Earth at UVic and Participated by Five West Universities)

- An Innovative Diesel – Fuel Cell - Battery Hybrid Green Vessel

- More Efficient Propulsion and Auxiliary Power Supply and Less Pollution

- Full power diesel mode with high ICE efficiency and lower emission

- Pure electric mode to avoid low efficiency, high emission and noise

- Introduction of innovative and environment friendly green shipping technology

- High Quality Electric Power Supply and Improved Working Environment

- Dramatically reduced noise and vibration

- Surge-free power supply

- Ideal for instrumentation and monitoring tasks in shallow water

- Maturing Canadian Technology into New Applications

- Based on Years of Fuel Cell Power System Research

These research and developments have been carried out in closed collaboration with leading industrial firms in hybrid powertrain and fuel cell technologies. These exciting projects as well as our recently acquired first-class GVT research, development and testing facilities have attracted exceptional students and provided them invaluable training on advanced mechatronics, automotive, fuel cell and hybrid vehicle technologies, and project management. The research program and facilities provide both direct and indirect supports to the emerging Green Transportation industry in British Columbia and Canada.

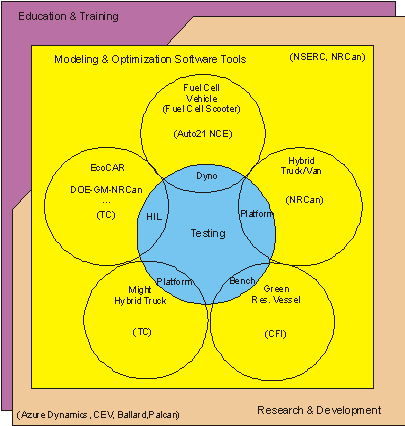

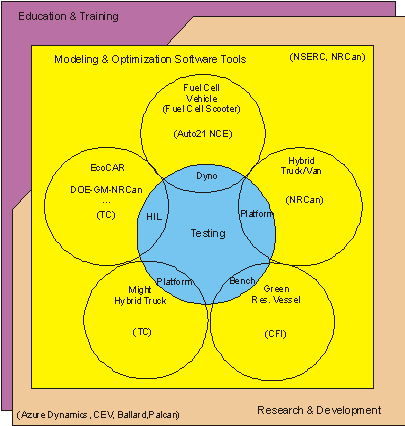

Relations of these closely related Green Transportation technology research, development and training activities and the new Green Vehicle Research and Training Centre are shown below.

understanding of the complex,

understanding of the complex,  multiple-mode hybrid powertrain architectures and to introduce the new global optimization based hybrid powertrain design method (past and present HEV design is largely trial and error based).

multiple-mode hybrid powertrain architectures and to introduce the new global optimization based hybrid powertrain design method (past and present HEV design is largely trial and error based). consumption and emissions while at the same time provide the consumer with a fully-functional and marketplace ready vehicle. The UVic EcoCAR team is

consumption and emissions while at the same time provide the consumer with a fully-functional and marketplace ready vehicle. The UVic EcoCAR team is  developing an innovative 4WD, two-mode plus, EREV on the 2010 Saturn VUE platform with a 2.4L flex-fuel (E85 ethanol capable) engine, GM 2-mode hybrid transmission, a UQM Powerphase 125 rear traction motor, a newly designed 21kWh A123 battery pack, as well as new vehicle electronic control unit (ECU) and power management system. The UVic team is proud to be one of 17 universities across North America selected to participate in this prestigious competition and to win the second place overall and six other major awards during the first year competition in June 2009. Drs. Z. Dong and C. Crawford are the faculty advisors of the UVic team. The UVic EcoCAR Team Awards include:

developing an innovative 4WD, two-mode plus, EREV on the 2010 Saturn VUE platform with a 2.4L flex-fuel (E85 ethanol capable) engine, GM 2-mode hybrid transmission, a UQM Powerphase 125 rear traction motor, a newly designed 21kWh A123 battery pack, as well as new vehicle electronic control unit (ECU) and power management system. The UVic team is proud to be one of 17 universities across North America selected to participate in this prestigious competition and to win the second place overall and six other major awards during the first year competition in June 2009. Drs. Z. Dong and C. Crawford are the faculty advisors of the UVic team. The UVic EcoCAR Team Awards include:

Over the past several years, the research team has developed and updated the semi-empirical PEM fuel cell stack and system models. The model was originally based upon the RMC Ballard PEMFC stack. The parameters of the model were changed using experiment data acquired from our stack tests on a Palcan 1.2 kW PEM fuel cell stack at UVic and improved with additional considerations. To effectively form a fuel cell hybrid electric vehicle model, we are integrating this PEMFC stack/system model into the vehicle performance model constructed using the new MathWorks SimDriveline vehicle powertrain modeling and simulation environment. This will provide us the flexibilities to explore various hybrid vehicle architectures, powertrain component sizes and control algorithms.

Over the past several years, the research team has developed and updated the semi-empirical PEM fuel cell stack and system models. The model was originally based upon the RMC Ballard PEMFC stack. The parameters of the model were changed using experiment data acquired from our stack tests on a Palcan 1.2 kW PEM fuel cell stack at UVic and improved with additional considerations. To effectively form a fuel cell hybrid electric vehicle model, we are integrating this PEMFC stack/system model into the vehicle performance model constructed using the new MathWorks SimDriveline vehicle powertrain modeling and simulation environment. This will provide us the flexibilities to explore various hybrid vehicle architectures, powertrain component sizes and control algorithms.

We have developed a customized dynamometer for tests of low-speed electric vehicles and fuel cell hybrid electric vehicles. At present, comparable studies on vehicle performance between the experiment results and simulation results, and on the performances of a battery electric vehicle and a PEMFC-battery hybrid vehicle (scooter for the simplicity of testing) with identical powertrain other than the power plants are under way with some preliminary results. More in-depth findings will be reported after the data are processed.

We have developed a customized dynamometer for tests of low-speed electric vehicles and fuel cell hybrid electric vehicles. At present, comparable studies on vehicle performance between the experiment results and simulation results, and on the performances of a battery electric vehicle and a PEMFC-battery hybrid vehicle (scooter for the simplicity of testing) with identical powertrain other than the power plants are under way with some preliminary results. More in-depth findings will be reported after the data are processed.